inquiry now

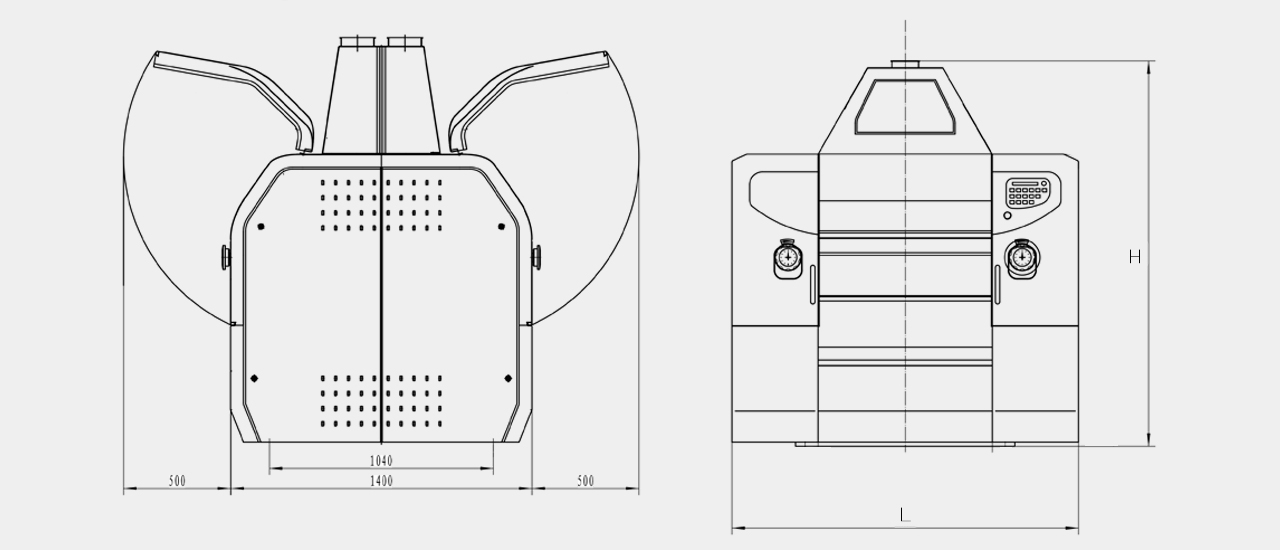

Roller Mill

Description & Features

The roller mill is the main equipment for milling section in flour mills. It mainly depends on a pair of differential transmission and relative rotation rolls to break wheat, meanwhile, scrapes endosperm from wheat bran, then endosperm grinding into flour. The material can be extruded, sheared and broken during the equipment working and so as to achieve a certain grinding effect, each roller mill has two independent drive, feeding, and grinding systems and play their functions in the flour passages.

- Flip the feed unit convenient, easy to clean the feeding area.

- The grinding roller, a spin off from the grinding body assembly, convenient operation, reduce parking time.

- Variable speed feeding, the feeding will increase to the limit, changing the feeding environment, improve the grinding quality, save energy.

- Permanent magnet synchronous motor speed control, and more efficient than ordinary motor, cleaner.

- Tooth elastic wedge belt tension device, can trace change automatic compensation, improve the service life of the band.

- The whole cast iron base, higher stability of equipment, contact parts in stainless steel to match the HACCP requirement.

- Double layer roller mill and direct pick up style are available.

Model |

Roll Size |

Gear Ratio |

Fast Roll Speed |

Dimension |

MMR25x80 |

250x800mm |

1.25:1, 1.5:1, 2:1, 2.5:1 |

450~650rpm |

1630x1400x1895mm |

MMR25x100 |

250x1000mm |

1.25:1, 1.5:1, 2:1, 2.5:1 |

450~650rpm |

1830x1400x1895mm |

MMR25x125 |

250x1250mm |

1.25:1, 1.5:1, 2:1, 2.5:1 |

450~650rpm |

2080x1400x1895mm |

Copyright © 2016.Company name All rights reserved.www.keywise-tech.com